A slurry pump is a type of centrifugal pump, lobe pump, or peristaltic hose pump in physics principle that increases the pressure of a liquid and solid particles. Slurry pumps are widely used in the transport of corrosive/abrasive and high-concentration slurries in many industries including mining, chemical, paper making, food processing, etc. There are different types of slurry pumps based on the transportation medium like water, air, or other fluids.

If you are looking for a slurry pump, then you may visit Schurco Slurry.

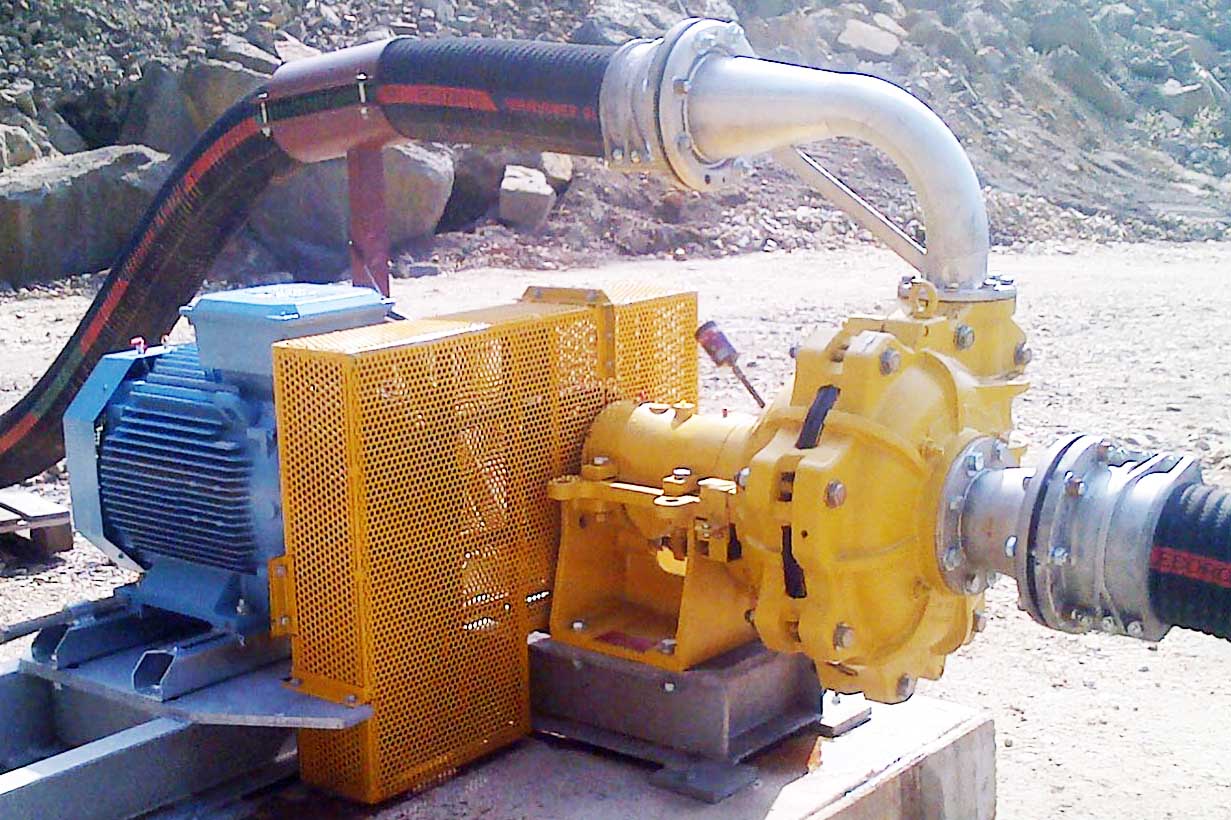

Image Source: Google

Slurry pumps work by using centrifugal force to pump water and solids through a pipe. The solids are suspended in the water and are moved along by the force of the water. The pump has a series of impellers that help to move the slurry through the pipe.

Slurry pumps are positive displacement pumps that are typically used to move liquids and semi-solid materials. The key benefits of using a slurry pump include:

1. Increased Efficiency: Slurry pumps are designed to handle viscous and abrasive fluids, which results in increased efficiency compared to other types of pumps.

2. Reduced Maintenance: The design of slurry pumps minimizes wear and tear, which reduces the need for maintenance and repairs.

3. Longer Life Span: Slurry pumps are built to last, with many models lasting for years with proper care and maintenance.

4. Versatility: Slurry pumps can be used in a variety of industries, including mining, wastewater treatment, food processing, and more.